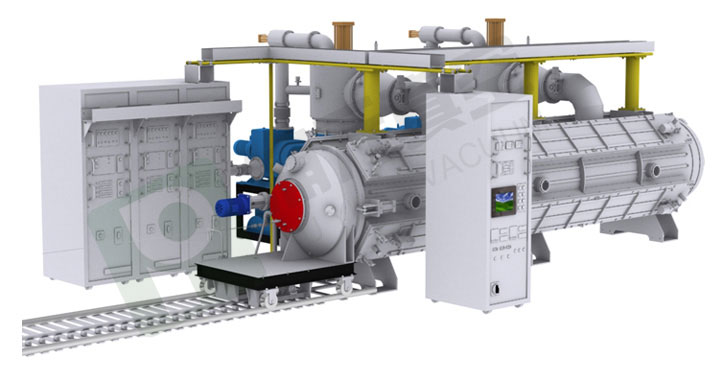

HLB Series Large-scale Sheet & Pipe Vacuum Coating Machine

Date:2016-01-13 10:16:58 Hits:4896

Ion coating is that the gas discharge portion of the evaporated material or ionized a vacuum chamber. As the gas or the evaporated material ion bombardment of particles, the evaporation material or reactants are deposited on the substrate. The glow discharge ion coating phenomenon, plasma and vacuum evaporation technology combine the three, not only can significantly improve the film quality, but also to expand the scope of application of the film. The advantage is that the film adhesion, and good diffraction, membranes, etc. extensively. Multi-arc ion coating and the general ion coating has a big difference. Multi-arc ion coating is used in arc discharge, rather than conventional glow discharge ion coating the deposition. In short, the principle of multi-arc ion coating cathode target is used as the evaporation source and the anode target by arc discharge between the shell, the target evaporation, thereby forming a plasma in the space, and be deposited on the substrate.

It can coat with the stainless steel, chrome, titanium, tungsten and other metal films, can also coat with alloy film or compounds, such as TiN, TiAlN, CrN film, horizontal multi-arc ion coating machine is mainly for large-area metal parts coated decorative film or feature film, applies to coat on stainless steel plate, stainless steel pipe, stainless steel door surface.

1) The maximum size of the vacuum chamber such devices can achieve φ5000X10000MM (long)

2) It is the machine that must be selected in large sheets, tubes coated on all kinds of decorative and functional film coating layer.

Model | HLB-1800 | HLB-2000 | HLB-3000 | HLW-2000 | HLW-3000 | HLW-4000 | HLW-5000 |

vacuum chamber dimensions | φ1800X2000MM | φ2000X2000MM | φ3000X3000MM | φ2000X6000MM | φ3000X6000MM | φ4000X8000MM | φ5000X10000MM |

vacuum system | A pair of

KT800

Diffusion pump unit | A pair of

KT1000

Diffusion pump unit | A pair of

KT1000

Diffusion pump unitX2 | A pair of

KT1000

Diffusion pump unit | A pair of

KT1000

Diffusion pump unitX2 | A pair of

KT1000

Diffusion pump unitX2 | A pair of

KT1000

Diffusion pump unitX4 |

Coating system | For many arc coating power target + + multi-function twin circular arc cylindrical arc target (optional) |

Coating auxiliary system | The low temperature ion secondary sources (except tool plating without heating system) |

Inflation system | Mass flowmeter | Mass flowmeter | Mass flowmeter | Mass flowmeter | Mass flowmeter | Mass flowmeter | Mass flowmeter |

Control mode | Manual or automatic | Manual or automatic | Manual or automatic | Manual or automatic | Manual or automatic | Manual or automatic | Manual or automatic |

Pumping rate | 5X10-3Pa

<15min | 5X10-3Pa

<15min | 5X10-3Pa

<15min | 5X10-3Pa

<15min | 5X10-3Pa

<15min | 5X10-3Pa

<15min | 5X10-3Pa

<15min |

Ultimate vacuum | 5.0X10-4Pa | 5.0X10-4Pa | 5.0X10-4Pa | 5.0X10-4Pa | 5.0X10-4Pa | 5.0X10-4Pa | 5.0X10-4Pa |

Remarks | Above equipment parameters for your reference only, specific according to customers' special requirement of practical process design |